• APRIL OFFERS with MASSIVE DISCOUNTS on POWER®, SHIRE™ and TGB™ • FREE ASSEMBLY on ALL TGB™ models inc. SUMMERHOUSES, PLAYHOUSES & SHEDS •

TGB™ DELIVERY: 2-4 Weeks*

*The current lead time for TGB Delivery & Installation to most areas is 2-4 weeks, although bespoke buildings, Tanalised® pressure-treatment, and delivery to remote postcode areas may take longer. At the moment, we are offering a FREE assembly service with these buildings, which will be done at the same time as delivery.

Description

TGB Rhino Apex Shed

The TGB Rhino Apex Shed is an immensely strong garden shed from one of the UK’s best manufacturers. It’s a traditionally built British garden shed, featuring high walls and ultra-heavy 75x50mm framing and this apex model also has ultra-heavy roof trusses.

The TGB Rhino Apex Shed is an immensely strong garden shed from one of the UK’s best manufacturers. It’s a traditionally built British garden shed, featuring high walls and ultra-heavy 75x50mm framing and this apex model also has ultra-heavy roof trusses.

The TGB Rhino Apex is manufactured using Scandinavian Redwood Pine from well managed sustainable forests, and is available in 10 sizes – 7×5 up to 12×10. All models are constructed using 16mm nominal (approx. 12mm finished) tongue and groove shiplap timber walls, along with tongue and groove roofs and floors, however this can be upgraded to a massive 22mm nominal thickness (approx. 18mm finished) if required.

Please note that NO chipboard or OSB is used in the construction of ANY TGB building. Our range of TGB buildings are available pre-treated in Honey Brown at no extra charge. You can choose from any one of 5 door positions at no additional cost, as well as one of the many options that are available for this range, including double doors, stable doors, opening windows, and additional security… please call for details.

Our TGB Sheds product range is second to none, featuring hundreds of great quality buildings, accessories and optional extras, however it is difficult to show everything fully on a single web page. We are an OFFICIAL PREMIER STOCKIST of all TGB products, therefore you are welcome to visit our Edinburgh display site to see the buildings in person.

Features

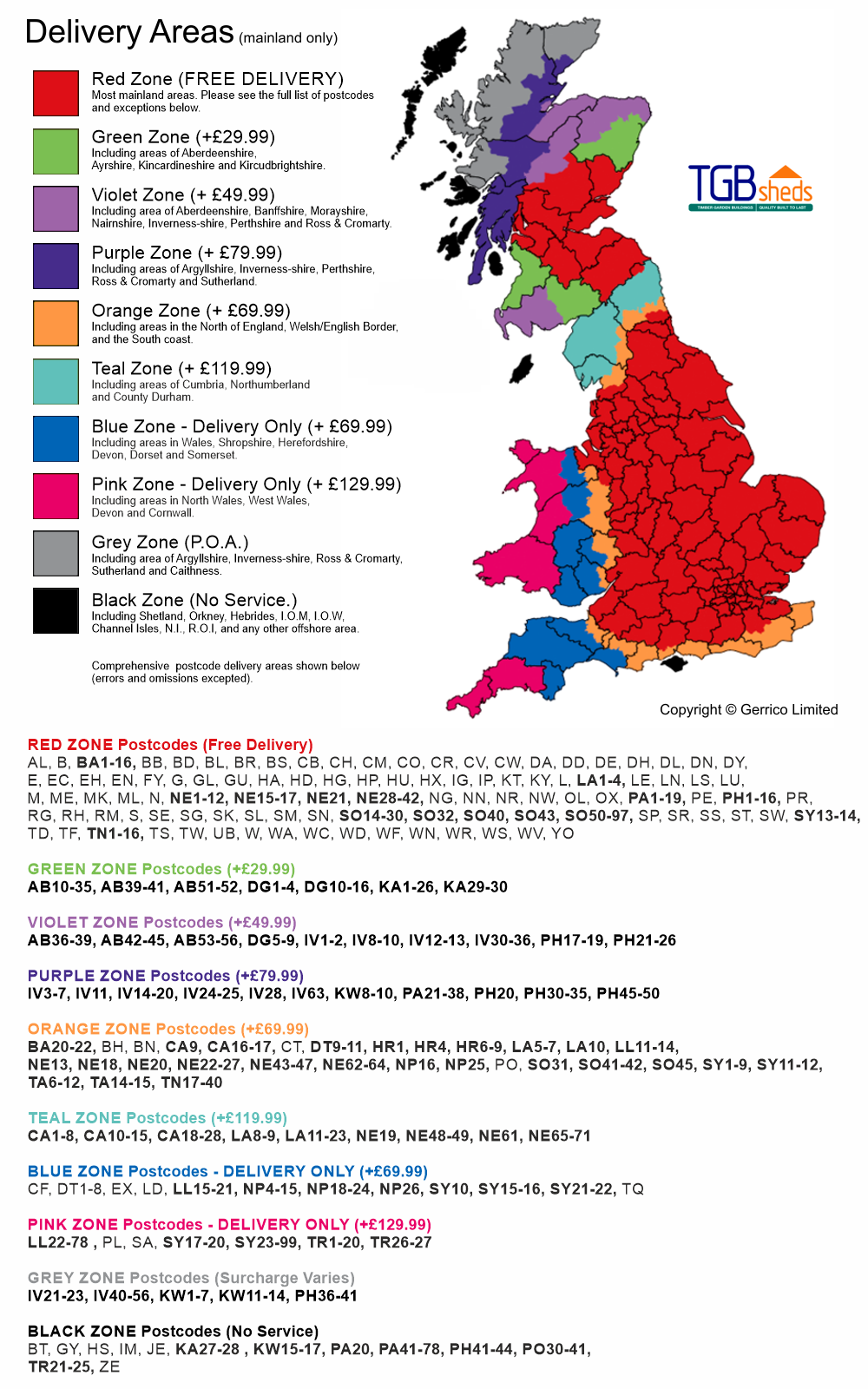

- FREE delivery*

- Professionally INSTALLED IN YOUR GARDEN*

- FREE preservative treatment

- Ultra-heavy 75x50mm framing

- Ultra-heavy roof trusses

- Heavy-duty box-framed door (boarded both sides)

- Heavy duty galvanised door hinges

- Mortice lock c/w keys and antique lever handles

- High walls and tall internal heights

- 5 different door positions (see below)

- Heavy 40kg mineral roofing felt

- Brown finish

- 16mm nominal (12mm finish) tongue & groove shiplap cladding

- High quality, slow growing Scandinavian timber

- T&G floor and roof

- 10x sizes from 7×5 up to 12×10

- Bespoke options available

Quality Construction

The TGB Rhino is made using EXTREMELY STRONG 75x50mm (nominal) framing. The entire building is manufactured using high quality, slow-growing, sustainable Scandinavian Pine from well managed, sustainably certified forests. All TGB Rhino Apex Sheds are constructed using 16mm nominal (approx. 12mm finished) tongue and groove shiplap timber walls, along with tongue and groove roofs and floors, however this can be upgraded to a massive 22mm nominal thickness (approx. 18mm finished) if required.

Please note that NO chipboard or OSB is used in the construction of ANY TGB building.

These TGB Rhino Apex Sheds are supplied pre-treated with an Eco-Friendly light brown preservative basecoat. Ultra-strong 75x50mm nominal (70x44mm finished) smoothed, rounded and planed framing has been used internally, which is doubled at the corners for extra strength. Mineral roofing felt is supplied to keep the roof watertight.

Preservative

TGB Rhino Apex Sheds are supplied pre-treated with a quality brown, non-toxic preservative base coat. This ensures that your garden building is ready to accept any preservative colour of your choice.

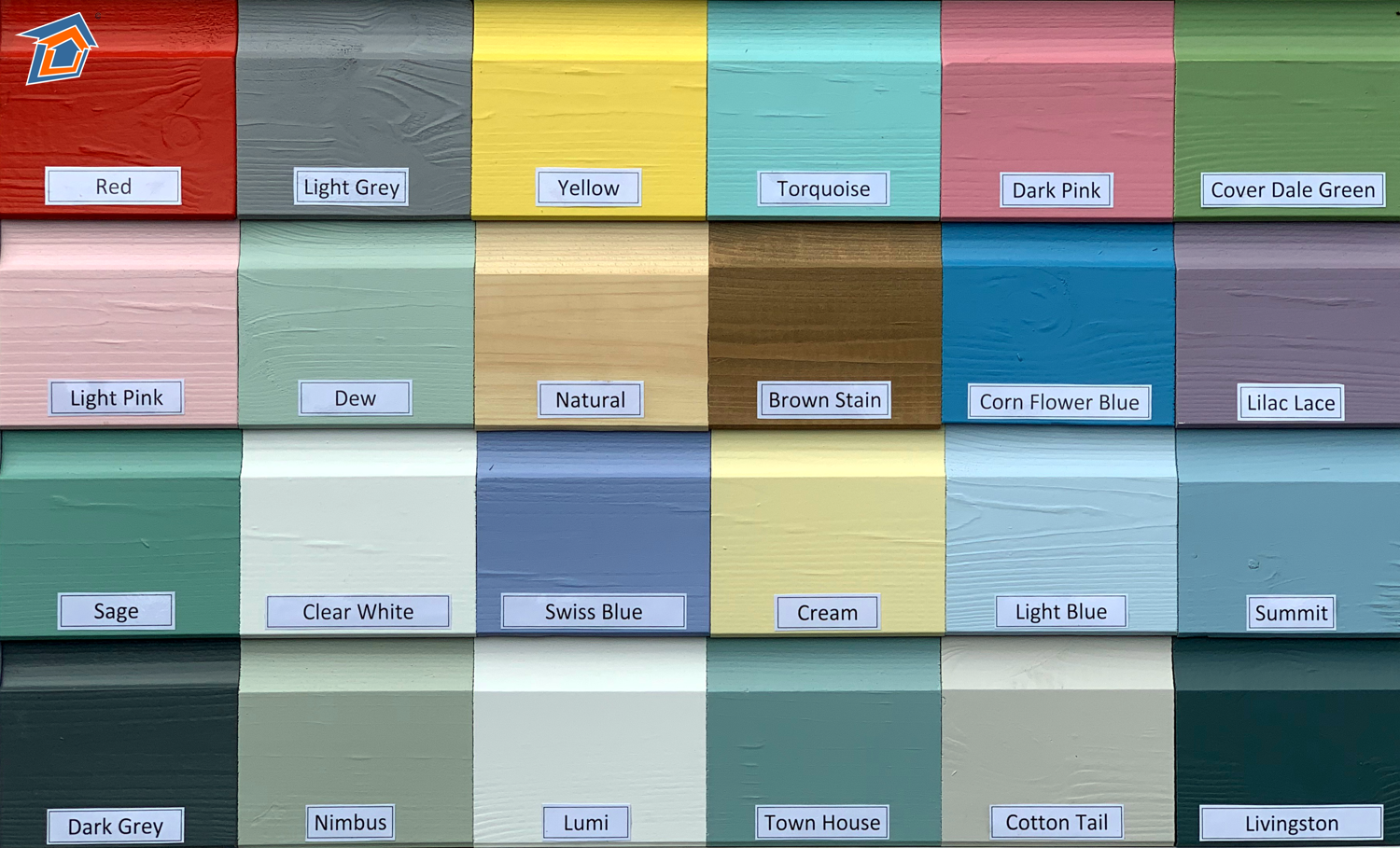

Alternatively we can supply them made from long-lasting Tanalised pressure-treated timber with a 15-year anti-rot warranty, or you can have your building factory-painted in a choice of 12x popular colours (maximum 2x colours per building). These look great, and don’t require any additional painting immediately… please contact us for details. Please remember that the colours shown below will look slightly different on your device, and from batch to batch.

Doors, Locking System & Windows

The TGB Rhino Apex Shed has a single box-framed door 762mm (30″) wide door is supplied galvanised hinges, and an internal mortice lock with 2x keys. Doors are twin-walled with cladding on the inside and the outside. They are hinged on the RIGHT as standard (although you can request hinging on the left if you prefer).

Sheds up to 10ft in length will have up to 3x fixed glass windows as standard, however 12ft long sheds will have up to 6x windows. Various options are also available, such as stable doors, double doors, and various security upgrades. Please ask for details.

Professional Assembly Included

We will install your TGB Rhino Apex Shed at NO ADDITIONAL CHARGE although some geographical limitations apply. Our PROFESSIONAL ASSEMBLY SERVICE covers approx. 90% of the UK mainland population, and requires non-restrictive access and a suitable base/site.

Look out for the FREE INSTALLATION logo:

DIY Assembly Video

Assembling the TGB Rhino Apex Shed yourself can be very satisfying and it has several advantages: you probably won’t have to wait as long for delivery, you can assemble it on a day suitable to you, and you can pre-treat the panels beforehand allowing the best possible protection for your building.

TGB Sheds, Playhouses and Summerhouses come with all the fixings and fastenings you need, but to make things even easier, here is an installation video that you can follow showing the assembly of a typical TGB building.

Optional Extras

This TGB Rhino Apex Shed is supplied as a full kit, complete with all necessary fixings, fastenings, glazing and roofing materials. Optional extras include professional assembly, framing and wall thickness upgrades, double doors, opening windows, heavy flooring, verandahs, log-lap cladding, toughened glass etc. The building can also be made to a bespoke size or configuration… please call for details.

Specifications

Please contact us prior to purchase if you have any queries regarding the dimensions, or if you require exact sizes. Roof overhangs will extend beyond the Body Size shown below (all dimensions are finished sizes).

| Model | Framing | Body Size (mm) | Height (mm) | Single Door (mm) | Windows*** | |||||

| TGB Rhino Apex Shed | (mm) | Length | Width | Eaves | Ridge | Height | Width | Fixed | Opening | |

| 7×5 | TGBRHINOA0705 | 70×44 | 2134 | 1524 | 1864 | 2260 | 1880 | 762 | 3 | 0 |

| 8×6 | TGBRHINOA0806 | 70×44 | 2438 | 1829 | 1864 | 2336 | 1880 | 762 | 3 | 0 |

| 10×6 | TGBRHINOA1006 | 70×44 | 3048 | 1829 | 1864 | 2336 | 1880 | 762 | 3 | 0 |

| 12×6 | TGBRHINOA1206 | 70×44 | 3658 | 1829 | 1864 | 2336 | 1880 | 762 | 6 | 0 |

| 8×8 | TGBRHINOA0808 | 70×44 | 2438 | 2438 | 1864 | 2475 | 1880 | 762 | 3 | 0 |

| 10×8 | TGBRHINOA1008 | 70×44 | 3048 | 2438 | 1864 | 2475 | 1880 | 762 | 3 | 0 |

| 12×8 | TGBRHINOA1208 | 70×44 | 3658 | 2438 | 1864 | 2475 | 1880 | 762 | 6 | 0 |

| 8×10 | TGBRHINOA0810 | 70×44 | 2438 | 3048 | 1864 | 2475 | 1880 | 762 | 3 | 0 |

| 10×10 | TGBRHINOA1010 | 70×44 | 3048 | 3048 | 1864 | – | 1880 | 762 | 3 | 0 |

| 12×10 | TGBRHINOA1210 | 70×44 | 3658 | 3048 | 1864 | – | 1880 | 762 | 6 | 0 |

***Window quantities will vary depending on door position.

All products are delivered sectional/flat-packed to kerbside unless stated otherwise. Information shown above has been supplied by the manufacturer, and is as accurate as possible (errors and omissions excepted), however they are intended only as a guide.

*The free installation service covers most of mainland Scotland, however delivery to outlying areas may be subject to an additional charge. We will contact you if you are in a chargeable area. This high quality building has an expected lifespan in excess of 15-years. We recommend that you install the building on a solid, free-draining base, with at least 60cm free space all around for maintenance and to avoid splashback.

You should treat all sections with a high quality, spirit-based preservative prior to assembly, and subsequently every year in accordance with the manufacturers instructions. Please ensure that regular general maintenance is carried out on all moving parts. Roofing felt should be regularly inspected, and replaced if required.

Reviews

There are no reviews yet